PREPRESS

HANTAM prepress service involves preparing digital files for printing by ensuring they are correctly formatted, including using the right resolution, color mode (CMYK), and file format (usually PDF). The process includes layout and proofing, color management, embedding fonts, preflight checks, and page imposition. Trapping is applied to prevent color gaps, and files are converted for printing plates. The final steps involve setting up the printing press and conducting press checks to ensure quality.

WHAT WE ARE GOOD AT

Final Artworks

We recognize that the FA process is crucial due to the numerous modifications required for the original digital copy. Our solution lies in the final digital file that surely impressing.

Color Separation

We deliver perfection in the final output. We refine color employing a four-color individual printing process, CMYK, to ensure each element we print radiates with precision.

Trapping

HANTAM offers a comprehensive solution to address Trapping issues that may arise in your final packaging, encompassing both Interactive and Automatic Trapping, utilizing predefined settings. What specific challenges are you encountering?

Color profiling

Our expertise also extends to color profiling, where we meticulously assess color balance, registration, and other critical elements to ensure necessary corrections are made prior to printing.

Color Reduction

Occasionally, certain products may exhibit inadequate color management, leading to printing costs that exceed budgetary. We have the capability to meticulously examine each color element within the artwork, which more efficient printing costs without compromising color visualization.

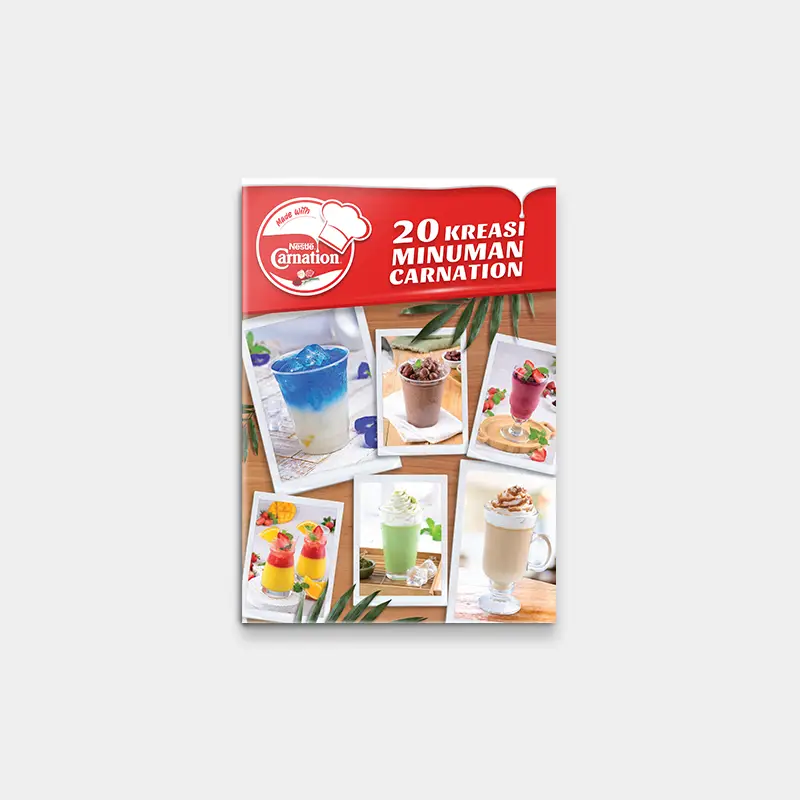

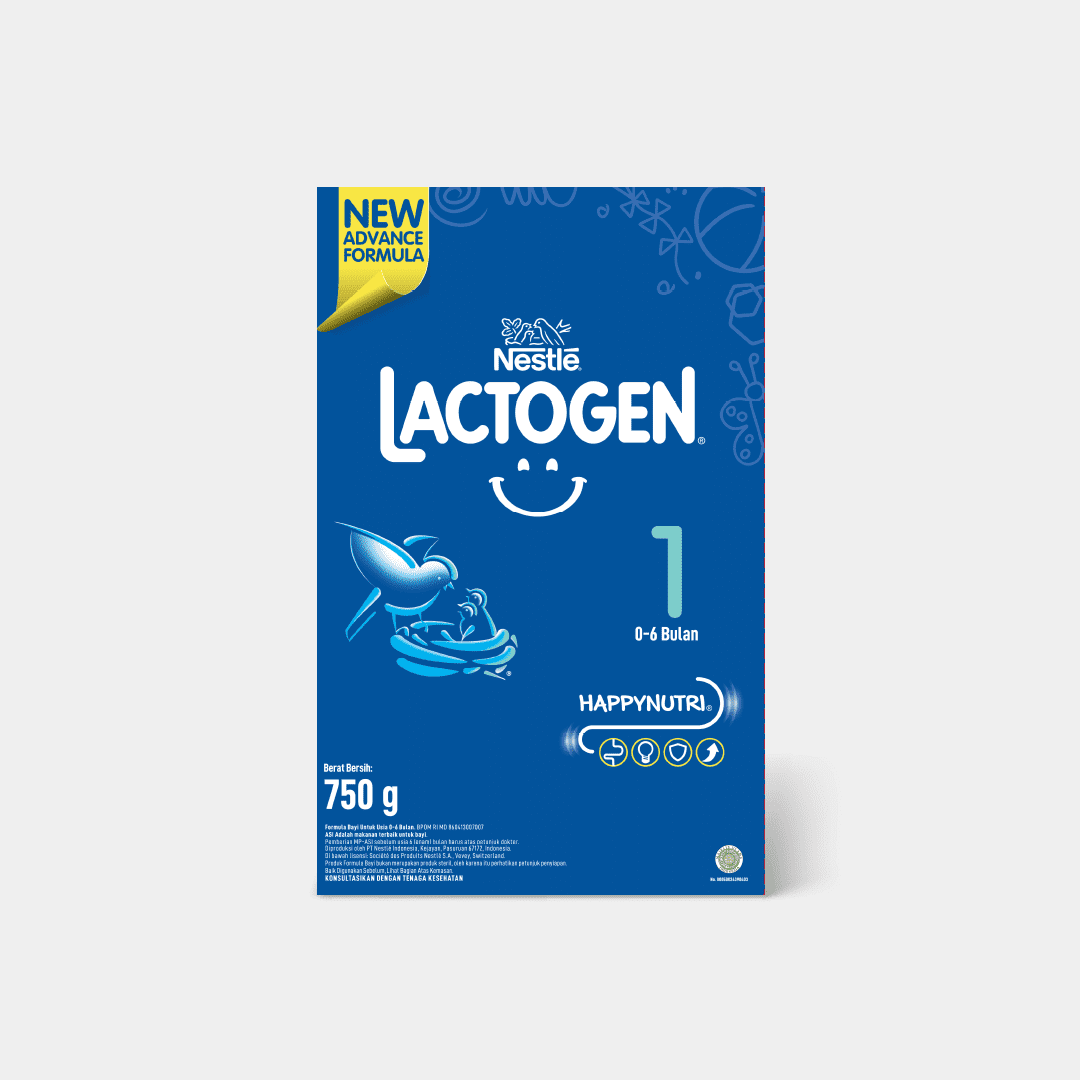

Digital Proof Print (ISO Standarized)

We enhance your printing project by delivering a meticulously validated final artwork. It’s more than the PDF file, we furnish a digital proof print that serves as satisfactory final result.

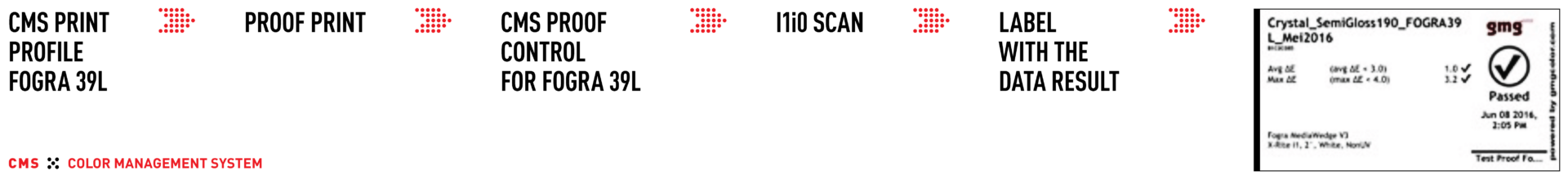

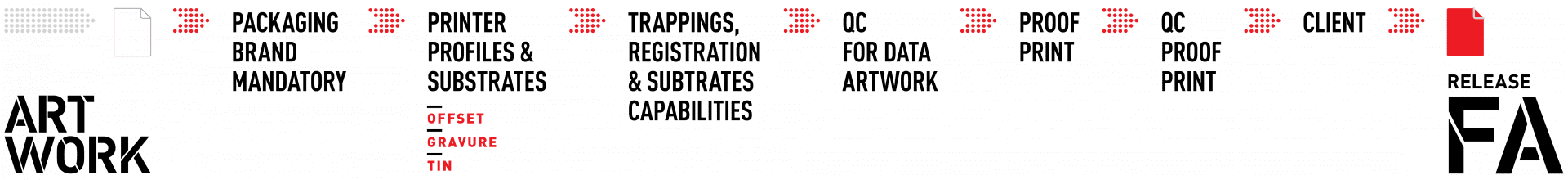

Our step to achieve perfect print

At HANTAM! Prepress Management, we simulate colors of your packaging design to your end production or printing supplier as a digital proof. You can see the outcome before the packaging is produced. We apply this technology to our clients, so, it helps to cut the production risks and lead times.

Print management benefits: Speed and accuracy, Accurate color from the beginning, soft proofing leads to cost saving.

Fogra 39L Standarization

A verified FOGRA 39L control strip is the most recognized color authentication worldwide as a proof quality. it guarantees reliable and give complete quality control of digital color proofs based on a defined standard. This is the only way to ensure that the proof simulates the subsequent printing process as accurately as possible. Errors occurring on the proof can be detected early on.